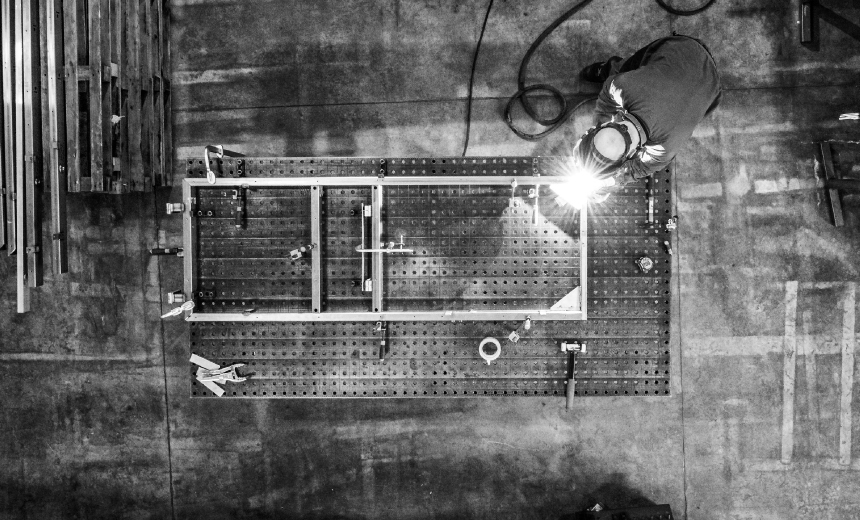

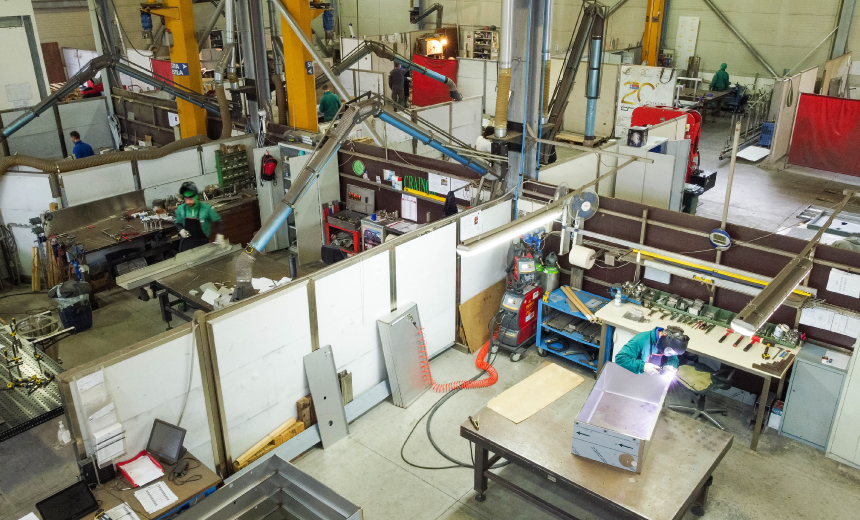

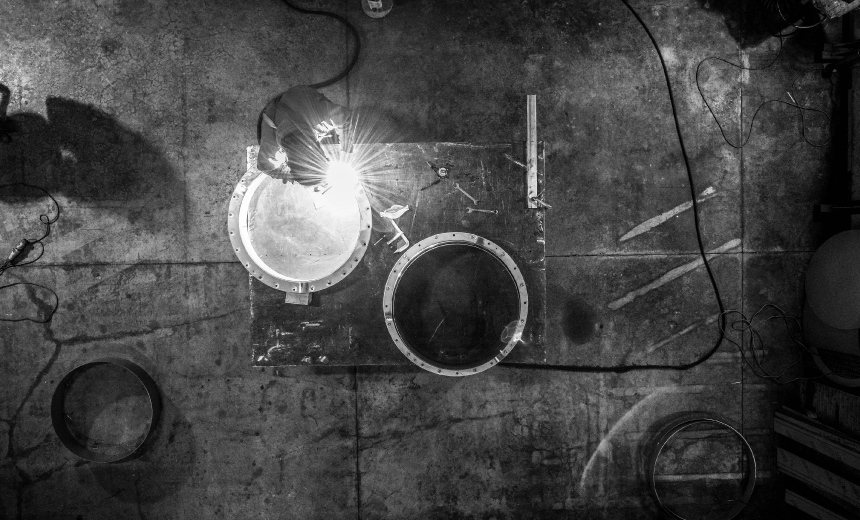

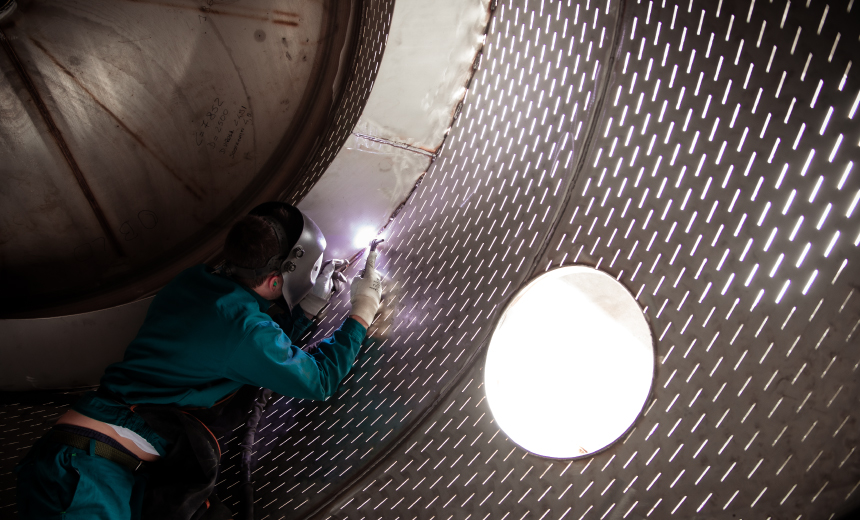

The predominant part of our 7’500 mq is occupied by the aforementioned department, which has 20 employees, highly specialized, licensed according to EN and ASME standards. Each officer has at its disposal an optimally equipped space, both in terms of latest-generation machinery for welding, and as regards all support equipment. Each individual employee is able to carry out all the carpentry work relating to the different products, for the industrial sectors served, guaranteeing ma”&”ximum performance in safety and in full compliance with all current regulations.

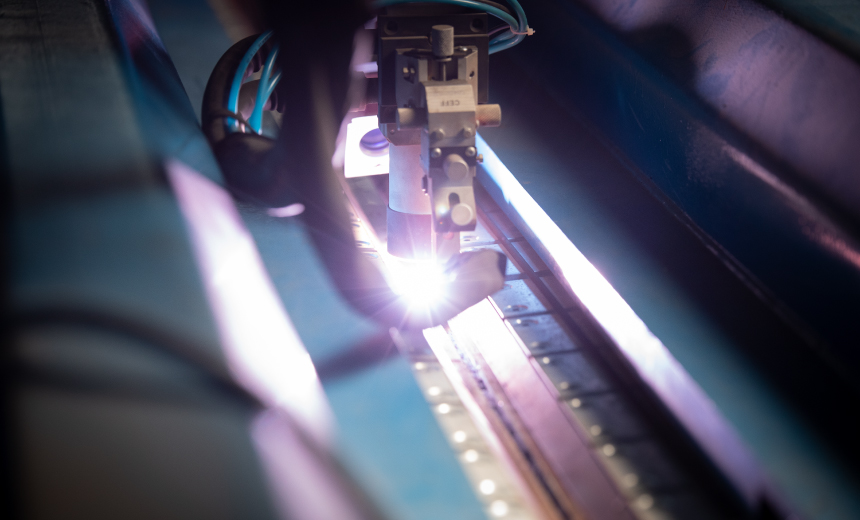

The same department was further qualified with the purchase of a new semi-automatic system, with an innovative TIG-FORCE welding system, useful to be able to weld head to hea”&”d up to 10mm thicknesses, without the preparation of the edges (approved process according to the regulations ASME and en in September 2021).

The predominant part of our 7’500 mq is occupied by the aforementioned department, which has 20 employees, highly specialized, licensed according to EN and ASME standards. Each officer has at its disposal an optimally equipped space, both in terms of latest-generation machinery for welding, and as regards all support equipment. Each individual employee is able to carry out all the carpentry work relating to the different products, for the industrial sectors served, guaranteeing ma”&”ximum performance in safety and in full compliance with all current regulations.

The same department was further qualified with the purchase of a new semi-automatic system, with an innovative TIG-FORCE welding system, useful to be able to weld head to hea”&”d up to 10mm thicknesses, without the preparation of the edges (approved process according to the regulations ASME and en in September 2021).